- Concrete Dyes Home

- Dyes vs. Stains: What are the differences?

- Sealing Colored Concrete

- Color Effects with Concrete Stains and Dyes

- Related Information

- Common Questions about Concrete Floors: Are they cold? Are they loud? Are they expensive?

- Comparison Chart of Concrete Coloring Products

- Other Resources:

- Concrete Contractors: Find Concrete Dyes

Concrete Dyes Expand the Color Palette of Concrete Stains

Although stains have received much applause for their amazing color transformations, dyes deserve equal kudos. These underrated coloring agents can achieve vibrant tones simply not possible with stains alone.

WHAT IS CONCRETE DYE?

Concrete dyes are translucent, penetrating color solutions. Unlike acid-based stains, they do not react chemically with concrete. Instead, they contain very fine coloring agents that penetrate into the concrete surface.

Both water- and solvent-based dyes are available, with each type having unique qualities. Dyes tend to produce tones that are more predictable and uniform than stains, but it's still possible to achieve interesting color variations.

Dyes are popular for coloring concrete floors in both commercial and residential locations. Find a concrete floor contractor near you that can help with your project.

Compare Coloring Products

Use this chart to decide between stains, dyes and other coloring methods.

Compare Coloring Products

Use this chart to decide between stains, dyes and other coloring methods.

Dyes vs. Stains

Find out what dyes are and how they differ from chemical stains.

Dyes vs. Stains

Find out what dyes are and how they differ from chemical stains.

Buy Concrete Dyes

Learn about buying concrete dyes, and how to use them effectively.

Buy Concrete Dyes

Learn about buying concrete dyes, and how to use them effectively.

Polished Concrete

Learn how concrete floors are polished to produce a high-gloss finish that never needs waxing.

Polished Concrete

Learn how concrete floors are polished to produce a high-gloss finish that never needs waxing.

Colored Concrete

Get an overview of the options for coloring concrete, and some tips for achieving stunning results.

Colored Concrete

Get an overview of the options for coloring concrete, and some tips for achieving stunning results.

Concrete Floor Videos

Watch 68 videos with expert design ideas, as well as installation & maintenance tips for interior concrete floors.

Concrete Floor Videos

Watch 68 videos with expert design ideas, as well as installation & maintenance tips for interior concrete floors.

More decorative contractors are using dyes to rev up their color palettes. Dyes are available in tones more vibrant than possible with most stains, such as red, yellow, orange, purple and cobalt blue. And the colors can easily be mixed at the jobsite or diluted to obtain a multitude of other shades.

Most dyes are packaged in concentrated form, allowing flexibility in the end color. They can be used full strength to attain greater depth of color or diluted with water or solvents to produce paler shades or simply a light wash of color. You can also intermix different colors of dye to produce your own custom hues.

CONCRETE DYE VS. STAIN

Dana Boyer, owner of Concretizen, uses concrete dyes as a normal part of her concrete flooring projects.

Dyes are nonreactive and impart color by penetrating concrete or other porous cementitious surfaces. They are much smaller in particle size than chemical stains or acrylic stains, thus allowing for easier penetration and color saturation while leaving less residue on the surface. The small dye particles fill the pores of the concrete and are very hard to remove, making dyes nearly as permanent as stains.

Dyes are available in water- or solvent-based formulations and produce looks ranging from opaque to translucent, depending on their application. Water-based dyes produce more marbling, while solvent-based dyes tend to be more uniform in color. Some water- and solvent-based dyes can be combined to produce special color effects. Dyes are not UV stable, so they are mostly recommended for indoor use.

Stains react chemically with the calcium hydroxide in concrete to impart color onto the surface. Their semi-transparent colors are mostly limited to earth-tones, though some more vibrant colors are available in water-based stains. Stains are UV stable, and can be used both indoors and outdoors.

Les Davis, developer of BRICKFORM'S Pro-Dye Plus had this important comment about concrete dyes: Translucent dyes penetrate the concrete drying in less than one minute in most climates with minimal cleaning required following the application. Therefore, the applicator completes the job about 60% faster than a typical acid stain due to reduced dry time and less cleaning.

CONCRETE DYE COLORS

Dyes take the color vibrancy up another level. Often used on polished concrete floors or to make bold graphics, logos or stenciled designs.

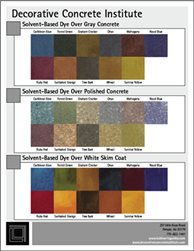

Sample color charts:

Here is a sample of possible colors for concrete using concrete dyes.

See more concrete dye color charts

CONCRETE DYE APPLICATION TECHNIQUES

Dyes can be applied in a variety of ways, depending on the results you want to achieve and the size of the job. Bob Harris, president of The Decorative Concrete Institute and author of Bob Harris Guide to Stained Concrete Interior Floors typically uses a high-volume low-pressure (HVLP) sprayer on his projects. Techniques vary for Dana Boyer, owner of ConcretiZen. "Every job is different. I may spray it, roll it, or brush it. There are many different ways to apply dyes," she says.

Regardless of the technique used, it is important to test the concrete surface for acceptance of the dye before application. The degree of penetration and intensity of color will vary depending on the application method used, age of the concrete, porosity of the concrete, cleanliness of the surface, and other general conditions. Some surfaces may not even accept the dye, particularly if they are dense and nonporous.

When applying dyes to an already stained surface, Harris recommends waiting until the stain achieves the desired look and intensity. The surface also should be clean and dry before dye application.

SURFACE PROTECTION & MAINTENANCE

Although dyes are formulated to penetrate into the concrete, it is still necessary to protect dyed and stained surfaces from wear and contaminants by applying a sealer.

If you protect the surface with a topical sealer and/or wax you get a very versatile floor. Most water-based, solvent-based, or urethane-based sealers are compatible with dyes.

Harris also recommends applying several coats of floor finish, or wax, to protect the sealer from wear. The sacrificial wax coating acts as a shock absorber to scuffs, scratches, and grime. Plus, it is easy to buff out a coat of floor finish and then reapply more if necessary. As long as the owner is diligent about ongoing maintenance and doesn't allow the floor finish to wear down to the sealer, dyed and stained concrete surfaces should last indefinitely.

DYED CONCRETE FLOORS

Polishing and enhancing cracks

Rather than hiding ugly cracks and hazing in a concrete floor, this creative contractor accentuated their beauty.

Polishing and enhancing cracks

Rather than hiding ugly cracks and hazing in a concrete floor, this creative contractor accentuated their beauty.

Combining stains and dyes

Concrete flooring artists can produce amazing special effects using a combination of stains and dyes.

Combining stains and dyes

Concrete flooring artists can produce amazing special effects using a combination of stains and dyes.

Making and ugly floor Beautiful

A residential floor that had been covered for years by carpet is beautifully transformed by the use of dyes.

Making and ugly floor Beautiful

A residential floor that had been covered for years by carpet is beautifully transformed by the use of dyes.

Adhesive stencils in action

Professional contractors use stencils can create a complex design or intricate logo on a concrete floor.

Adhesive stencils in action

Professional contractors use stencils can create a complex design or intricate logo on a concrete floor.

Concrete Contractors: Find Concrete Dye Products and Suppliers