Aldie, VA

Stamped concrete is textured, patterned or imprinted to look like stone, slate, tile, brick and even wood. The wide variety of pattern and color choices make it popular for beautifying patios, pool decks, driveways and more. Additionally, it's an affordable paving option that requires less maintenance than other materials.

Find stamped concrete contractors near me.

Popular Resources

Stamped Concrete Pictures

Browse hundreds of pictures of stamped concrete patios, pool decks and more in our photo

Stamped Concrete Patterns

Discover the most popular patterns for stamping concrete including cobblestone, slate and more.

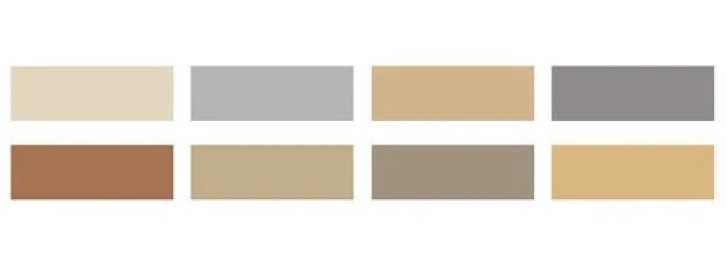

Stamped Concrete Colors

Learn how stamped concrete is colored and see what color options are available.

Concrete Design Videos

Learn how stamped concrete is colored and see what color options are available.

Stamped Concrete Cost

Learn how stamped concrete is colored and see what color options are available.

Stamped Patios

Learn how stamped concrete is colored and see what color options are available.

Because of its superior durability and weather resistance, colored and stamped concrete is the perfect choice to bring the high-end look of stone, brick, or wood to patios, pool decks, driveways, walkways and courtyards.

Check these out for ideas, design tips and examples: