- Concrete Polishing Equipment

- Get the Look - Polished Concrete Pictures

- How to Polish Concrete: Learn the basics and get a step-by-step overview

- Polished Concrete Preparation: How to clean, repair, and evaluate before polishing

- Concrete Polishing vs. Resurfacing

- Reviews of Concrete Polishing Equipment How to clean, repair, and evaluate the condition of concrete floors before polishing

- Tips on Using Polishing and Grinding Equipment

- Tips for Choosing Edge Grinders

- Selecting Dust-Collection Equipment

- Diamond Tooling: Tips for choosing the right type of diamond tooling and equipment

- Concrete Densifiers: An introduction to chemical hardeners and how they work to improve polished concrete

- 2023 Polishing Techniques: An online interview series featuring Bob Harris

Diamond Tooling for Polished Concrete

Tips and insights on choosing the right type of diamond tooling for polishing concrete floorsFor years, concrete floors were considered utilitarian and functional at best, with no perceived aesthetic value. How ironic that polished concrete today is one of the most sought-after flooring alternatives in many different market sectors, including heavy and light commercial, tenant improvement, and residential to name a few. Just last month, we flew to Arkansas to consult on a high-end polished concrete floor, and when we got off the plane at the local airport, most of the floors were beautifully polished concrete, which is a testament to where this finish is being accepted and used. Clients choose polished concrete surfaces for a variety of reasons, including the unique stone-like appearance, high light reflectivity, and the huge reduction in annual maintenance costs. What’s more, polished concrete is an environmentally responsible system that lends itself to LEED projects.

Although the grinding equipment is an important part of the puzzle to producing these one-of-a-kind floors, the true workhorse is the diamond tooling. Learning how to successfully polish concrete starts with having an understanding of using the appropriate grit and type of diamond tooling relative to the substrate you are working on as well as the desired effect you want to achieve, such as coarse-aggregate exposure, a sand finish or a cream finish. It is your responsibility as the contractor to understand what role the diamond tool plays in the process.

Unfortunately, the popular maxim “diamonds are forever” is not the case in the industry of grinding, honing and polishing concrete and cement-based toppings. I’m reminded of a story of a local contractor calling me crying the blues about how fast his diamonds were wearing out and that he was not getting any support from his supplier. It was determined that he was using a soft-bonded diamond on extremely soft concrete (we’ll get to why that’s a problem later). The result was that he was getting less than 1,500 square feet of use per set of diamonds when he should have been getting roughly 7,000 to 10,000 square feet per set with the appropriate bond. Talk about lack of productivity!

It’s mind boggling to see how the polishing industry has evolved through the years, especially when it comes to advancements in diamond tooling. Just when you think you have perfected a certain sequence with a certain type of diamond tooling, along comes a later and greater version that cuts faster and polishes to a higher degree of shine. Yet despite these advancements, the essence of how diamond tooling works its magic hasn’t changed. Here are the basics you need to know to get the most productivity from your diamond tooling, along with some insights from industry experts on how to achieve the best results with today’s systems.

Diamond Bond Basics

The term bond refers to the matrix in which the small chips of diamonds are suspended. For example, metal bond refers to a metal matrix and resin bond refers to a resin matrix that suspends the diamond chips. Although this is a very basic analogy, think of a chocolate chip cookie, with the chips being the diamonds bound together with the cookie dough. To achieve the greatest productivity, the diamonds always need to be exposed so they do what they are supposed to do, which is cut or polish the concrete surface. That means that on hard concrete, a soft-bonded diamond needs to be used, whereas on soft concrete a hard-bonded diamond needs to be used.

Another important term used in diamond tooling is the segment, or the raised part of the tool that holds the metal or resin bond. There are a variety of different tools with varying amounts of segments. Often you will hear the term “single seg” or “double seg,” which refers to how many segments are mounted on each tool. More segments on the mounting plate means less head pressure, whereas if you use only a single segment, all of the head pressure is on that one segment.

Early on in the polishing industry, diamond tooling only consisted of metal bond and resin bond. In today’s market, the list now includes hybrid or mixed-resin diamonds, which are usually a blend of both resin and metal bonds within the same segment, and PCDs, which are polycrystalline scrapers commonly used to remove coatings and mastics.

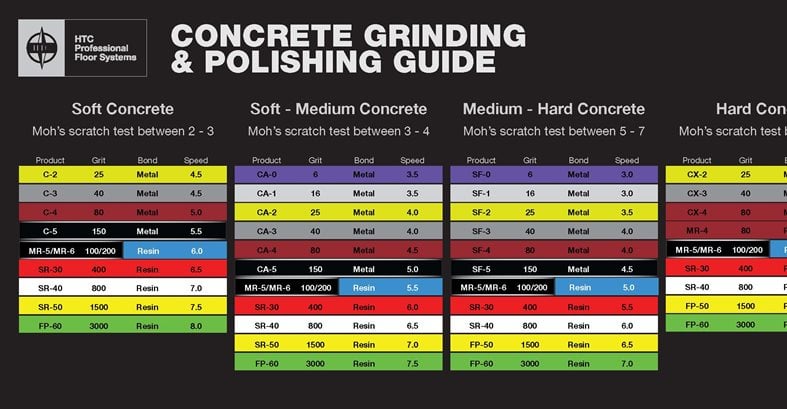

Another important factor when choosing the proper tooling is understanding how hard or soft the concrete is. Knowing whether you are working on soft, medium or hard concrete enables you to purchase the correct bond of the tools and dramatically increase productivity. Some manufacturers have grinding guideline charts to help contractors find the corresponding type and bond of the diamond needed for the particular hardness of the concrete. One way to determine the hardness of the substrate is to conduct a Moh’s hardness scratch test. The Moh’s scale ranks the hardness of minerals on a scale of 1 to 10, with 1 being the softest and 10 being the hardest. Concrete usually falls somewhere between 4 and 8 on the Moh’s scale.

To further complicate the selection process, diamond tooling is available in various grits, which refers to the size of the diamonds within that tool. The lower the number of grit, the larger the size of the diamond. Conversely, the higher the number, such as 800, 1500, or 3000, the smaller or finer the grit. Unfortunately, when it comes to the proper sequencing of diamond tooling, you can’t take a one-size-fits-all approach. Finding the right diamond combination relative to the actual concrete you are working on is the key to achieving maximum productivity.

Polishing Diamonds

Options for hard, medium, and soft concrete.

Polishing Diamonds

Options for hard, medium, and soft concrete.

CPS G-170 Electric

17" Floor Grinder 230 volt ($7,600)

CPS G-170 Electric

17" Floor Grinder 230 volt ($7,600)

Propane Concrete Polisher

Concrete Polishing HQ

Propane Concrete Polisher

Concrete Polishing HQ

Scanmaskin Diamond Tools

A wide variety of different sizes and hardness

Scanmaskin Diamond Tools

A wide variety of different sizes and hardness

Lythic Densifier XL

1 Gallon & 5 Gallon sizes

Lythic Densifier XL

1 Gallon & 5 Gallon sizes

Diamond Tooling and Pad Insights from the Experts

To get expert insights on diamond tooling, I interviewed John Abrahamson, national sales and marketing manager for SASE Company, a manufacturer of grinding equipment and diamond tooling, and Carlos Perez, owner of Custom Concrete Specialists, Miami, which does some extremely high-end concrete polishing work.

I figured it would be advantageous to get some expert insights on recent advancements in diamond tooling and how to achieve the best results with today’s systems. I spoke with John Abrahamson, national sales and marketing manager for SASE Company, a manufacturer of grinding equipment and diamond tooling, and Carlos Perez, owner of Custom Concrete Specialists, Miami, which does some extremely high-end concrete polishing work.

Abrahamson

Harris: What have been the biggest changes in diamond tooling from the 1990s compared to today?

Abrahamson: The most significant change in metal-bond diamond tooling since the ’90s is the number of options of matrix or metal bindings used. In the ’90s there were only a couple of different metal bindings or matrixes. Now there are typically six different bonds, ranging from very soft to very hard. Another significant change would be the introduction of a hybrid type diamond tool where you have a metal-resin combination. This allows you to make a nice transition from the metal-bond step to the resin-bond step. The hybrid tool is also very good for making the initial cut in certain applications.

During the final stages of polishing, you’ll work up to higher grit levels for finer polishing. Here 3000-grit resin-bond diamonds are doing their job.

Harris: For someone new to concrete polishing, what is your best advice as it relates to choosing diamond tooling?

Abrahamson: Newcomers to the polished concrete business will save themselves thousands of dollars in diamond tooling and labor if they are well educated on which bonds are best to use on the particular floors they are grinding.

Harris: Do you see the industry changing more to an all-resin system for all steps, or do systems still predominantly consist of metal-bond diamonds for the lower grits and resin-bond diamonds for the higher grits?

Abrahamson: The industry will always have a need for a metal grind followed by a resin polish. The scenarios where resins are taking over the part of the metal bonds are found primarily where an inexpensive alternative is needed, and in that case all that is really being accomplished is a polishing of the cream on the surface of the floor. An all-resin polish will improve the cleanablity of a floor, but it will not remove the imperfections from a concrete floor.

Harris: What is your opinion of the applicators and manufacturers that are promoting the topical-polishing-only systems using diamond-impregnated pads instead of the traditional full grind, hone and polishing steps?

Abrahamson: I see no problem with that as long as they differentiate it from a full grind and polish and do not oversell the topical polish, making unrealistic claims. Topical polishing and traditional full grinding, honing and polishing are two totally different scenarios.

Using coarse lower-grit diamonds and walking with the machine too quickly can leave deep scratches in the floor that are difficult to remove.

Harris: What percentage of your customers grind dry vs. wet and why?

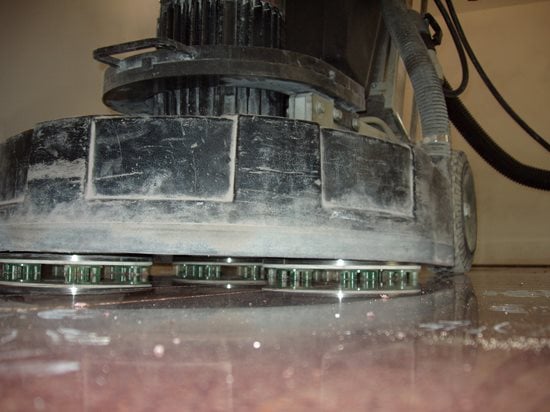

Abrahamson: About 90% to 95% of my customers grind dry for a variety of reasons. Primarily, grinding dry means that you do not have the messy slurry to clean up, let alone dispose of. Also, grinding dry allows the equipment operators to better see the floor during the grinding phase, whereas grinding wet sometimes hides the low spots since the floor is saturated.

Harris: I know concrete varies in hardness, but what is the average life expectancy (square feet per set of diamonds) one could expect to get?

Abrahamson: When using the proper metal-bond diamonds, you should expect to get about 7,500 to 10,000 square feet out of a set of metal bonds. If you get more than 10,000 square feet, you are typically losing productivity due to the diamonds grinding too slowly. On a lower-grit resin, such as a 100, 200 or 400 grit, you can expect anywhere from 1,000 to 4,000 square feet depending on the style of resin used. On a higher-grit resin, such as an 800, 1500 and 3000 grit, you can expect to get anywhere from 3,500 to 10,000 square feet.

Perez

Harris: When you were first starting out in the art of polishing, what was the hardest learning curve or best lesson you had to unfortunately experience?

Perez: The hardest lesson was learning to be patient and to take my time on the first two cuts to achieve a scratch-free floor. I wanted to do it faster. In concrete polishing, it doesn't work like that. The first two steps are probably the most important since they set the stage for the rest of the process. Take your time, and you will have a gorgeous floor.

Harris: What have been the biggest changes in diamond tooling today compared to when you first started?

Perez: One of the biggest changes is that before you had to go through 7 to 10 steps to polish a floor. Nowadays there are different kinds of systems, like hybrid pads, that permit you to complete the process in just 4 steps.

Harris: In working with different contractors all over the world, I have noticed that some contractors use different tooling manufacturers for various grits. Some claim that certain metal-bond diamond tooling from one manufacturer may cut better than others, while another manufacturer’s resin-bond diamond tools polish better. Do you use a variety of different manufacturers, and if so, why?

Perez: Yes, we use different manufacturers, and this depends on the job and the type of finish the customer wants. For metal-bond cutting, we use Korean diamond tooling because it gives us a lot more square feet per set. For resins, everything depends on the type of concrete, Sometimes we use metal-resin hybrids for the initial cuts if the concrete is new and or if the customer does not want aggregate exposure.

Harris: I know your company polishes a lot of cement-based overlays. What is the biggest consideration when choosing the appropriate tooling for polishing these types of toppings?

Perez: Custom Concrete Designs only uses Rapid Set TRU (a self-leveling overlay from CTS Cement) for polished overlays. All the big diamond tooling manufacturers have systems to polish these types of products. We use a variety of tooling consisting of Korean and Chinese soft-metal bond and resin diamond tooling.

Harris: When you are embedding objects into your overlays, often the embedded objects are protruding above the surface. What types of tooling have you had the best success with to grind the surface flush without dislodging the embedments?

Perez: When I’m building an overlay with a lot of inserts and different types of aggregates I like to do my first cuts with a round 3-inch soft-metal bond diamond, which is then followed with a transition hybrid pad.

Related resources:

Checklist of Polishing Equipment & Supply Needs

Polishing, Buffing & Burnishing Tools Videos