Cutting Concrete with Diamond Saw Blades

8 tips for how to cut concrete using diamond bladesWhether you're sawing control joints, enhancing concrete with decorative scoring, or cutting out existing concrete for patching or replacement, you can't do the job without a top-quality saw blade. But like a master chef who needs an assortment of knives to prepare various gourmet specialties, you can't rely on just one type of blade to do all these cutting tasks well, or even to perform the same task in different types of concrete.

Diamond saw blades are typically the best choice when it comes to making clean, professional cuts in concrete. However, within this category, you'll find myriad blade options at a wide range of price levels. How do you choose the perfect blade for the job at hand?

To achieve optimum cutting performance for your investment, follow these eight tips:

Tip 1: How Do Diamond Blades Work?Understanding how a diamond blade works will help you choose a blade with the right characteristics and cutting quality for your needs. Here are the four basic blade components:

- The metal core, a precision-engineered steel disk with a segmented rim that holds the diamonds.

- The synthetic diamond crystals, the sharp cutting teeth that slice through the concrete.

- The matrix, a metal bond that holds the diamond particles in place until they wear away.

- The weld, which attaches the cutting segments to the core (most segments are laser welded or soldered).

The exposed diamonds on the surface of each segment do the cutting, using abrasive action to slice through material as the blade rotates at high speeds. As the diamonds at the surface become dull through use, the matrix begins to shed away to release the worn diamond crystals and expose new, sharp diamonds embedded within the matrix.

The most important fact to know is that the hardness of the matrix controls how quickly a blade wears. Here's the basic rule: A diamond blade used to cut soft, abrasive materials (such as uncured, green concrete) should have a hard metal bond so the exposed diamonds are fully utilized before they shed away. Conversely, a blade for cutting hard, nonabrasive concrete should have a soft bond to allow for easier erosion of the matrix, which will ensure exposure of new, sharp diamonds when you need them.

Tip 2: Cut Concrete with the Right Diamond BladeFor maximum cutting speed and blade life, you should match the blade as closely as possible to the material you're cutting. Characteristics of the concrete you need to know include the compressive strength, the size and hardness of the aggregate, and the type of sand.

Blade manufacturers consider concrete with a compressive strength of 3000 psi or lower a soft material and concrete with a strength above 6000 psi a hard material. Therefore, you should use a blade with a hard bond to cut the lower-strength concrete and a blade with a soft bond to cut high-psi concrete. Similarly, hard aggregate (such as trap rock, basalt, and quartz) dulls diamond particles quickly, so use a blade with a softer bond to allow new diamonds to be exposed as needed.

The size of the aggregate in concrete primarily affects blade performance. When cutting through larger aggregate (3/4 inch and up), the blade cuts and wears more slowly. Pea gravel (smaller than 3/8 inch) is easier to cut, but the blade will wear faster.

The type of sand determines the abrasiveness of concrete, with sharp sand being the most abrasive and round sand the least. To determine the sharpness of the sand, you need to know where it's from. Crushed or river bank sand is usually sharp while river sand is round and nonabrasive. The more abrasive the sand, the harder the bond requirement.

What if you will be cutting more than one type of concrete? As a general rule, manufacturers recommend choosing the blade based on the material you'll be working with most often or the material for which top blade performance is most important. Most diamond blades can cut a range of materials.

Tip 3: Cutting Concrete at the Right TimeIf you're placing new concrete, you have the option of cutting control joints while the concrete is still green (about 1 to 2 hours after finishing) or the next day after the concrete has hardened. The timing of the cut will dictate the type of blade you select.

Some decorative concrete contractors prefer to cut concrete while it's still green because it minimizes the occurrence of ugly random cracking (especially in warm weather, when concrete hydrates faster) and permits shallower joint depths of an inch or less. However, green concrete will be softer and more abrasive than the same concrete in a cured state. That's because the sand in the mixture hasn't yet bonded to the mortar and it acts as an abrasive. Blade manufacturers offer hard-bonded diamond blades specifically for cutting green concrete.

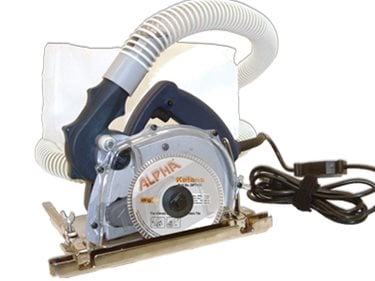

Tip 4: Wet Cutting Concrete vs. Dry Cutting Concrete - How to DecideOften the decision of cutting wet or dry depends on your preference and job requirements. Dry cutting eliminates messy wet slurry and the need to equip saws with water tanks and hoses. Using a blade wet, on the other hand, reduces dust but makes it necessary to contain or clean up the slurry. For indoor jobs where you need to keep the work area dry, a dry-cutting blade and compatible saw may be your only option.

The main difference between wet and dry blades is the weld (as described in Step 1). Dry-cutting blades have segment welds that resist heat and don't require water for cooling. They are usually intended for intermittent cutting and for use on handheld, low-horsepower saws. If you're sawing decorative pattern lines in concrete, dry-cutting blades are often the best choice for making crisp, clean cuts (see Sawing and Patterning). These decorative cuts are typically only 1/16 to 1/4 inch deep and do not function as control joints.

Wet-cutting blades are typically used with walk-behind saws for cutting joints in cured concrete flatwork because water cooling permits deeper cuts. Although it's possible to use most dry-cutting blades with water, never use a wet-cutting blade dry. Always continuously cool the blade with water to avoid segment loss and blade warpage.

Walk Behind Skilsaw

7" worm drive, adjustable handle

Walk Behind Skilsaw

7" worm drive, adjustable handle

Joint Clean-out Saw 13HP

Cleans joints at a rate of 20-60 fpm.

Joint Clean-out Saw 13HP

Cleans joints at a rate of 20-60 fpm.

Blade Roller

For worm drive saws - $139.28.

Blade Roller

For worm drive saws - $139.28.

Tip 5: Concrete Blades Compatibility with Sawcutting EquipmentWhat type of handheld saw or flat saw are you using? What is the horsepower and operating speed (or rpm)? Blade manufacturers provide charts with recommended operating speeds and maximum safe operating speeds for their blades. You'll also find this information stamped right on the blade itself.

Always match the blade with the speed range of the saw. Operating the blade at a lower speed than recommended can diminish its cutting life and performance. Exceeding the blade's maximum rpm rating can damage the blade and risk injury to the saw operator.

Other factors to consider:

- Blades designed for wet use only must be operated by saws that can deliver a continuous supply of water to cool the blade.

- Most blades for cutting green concrete are designed for use with special early-entry saws that minimize joint raveling and spalling.

- Don't use a blade that exceeds the maximum blade diameter and cutting depth capacity of the saw.

Tip 6: Concrete Cutting Blades - Performance vs. CostManufacturers typically offer diamond blades at various quality and cost levels, ranging from basic economy to top-of-the-line premium or professional versions. Generally the key difference among these options is the diamond content, which is the greatest raw material cost in manufacturing the blade. Moving up from a standard to a premium blade may boost the cost 20% or more, but you'll get a higher concentration of diamonds and significantly longer blade life.

Basically, you need to decide what's more important: the initial cost of the blade or total sawing cost. For small cutting jobs where you won't be giving the blade much of a workout, you may save money by going with the economy blade. For large jobs or frequent use, a top-quality blade may actually be less expensive in the long run based on a cost-per-cut breakdown.

A premium-quality diamond blade isn't cheap. Expect to pay several hundred dollars or more, depending on the blade diameter. If that's more than you're willing to invest for an occasional cutting job, consider hiring a professional sawing contractor to do the work. To locate a contractor in your area, visit the member directory of the Concrete Sawing & Drilling Association (CSDA).

Tip 7: Diamond Cutting Blades for Decorative ConcreteWant to achieve the look of a decorative hand-tooled joint without all the labor? It's possible by using beveled saw blades with a special cutting edge that produces chamfered or radiused cuts in green concrete. Learn more about the applications of these blades for decorative concrete projects.

Tip 8: Concrete Blade Codes from CSDAIf you follow all of the steps, you will be armed with the information necessary to find exactly the type of diamond blade you'll need for your next sawing project. Now it will be easier than ever to identify whether a certain blade meets your requirements thanks to a new blade application code (PDF) developed by CSDA and endorsed by the Masonry and Concrete Saw Manufacturers Institute (SMI).

The code, which is in a three-letter format separated by dashes, will be permanently imprinted on the blade. And it will tell you at a glance whether the blade is for wet or dry use, what type of material it can cut, and the saw type it's designed to work with.